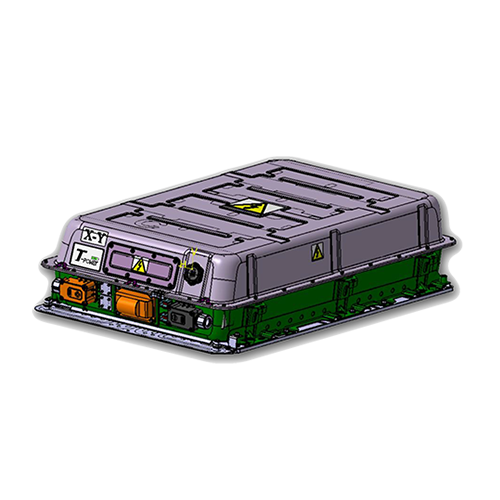

Energy Storage Assembly

PD-SK

Compatible with the full range of T-POWER electric vehicles;

External water-cooling system will enable battery capacity derating lower than 20% in 8 years;

Optimization on DC charging strategy can meet commercial operation requirement. No additional charging is required all day. Charging on high temperature condition can be avoidable.

| More specifications | |

|---|---|

| Functional integration | Battery pack, cooling system, accessories |

| Applicable models | Full range of T-POWER electric vehicle |

| Coolant ratio | Water/Ethanol (1:1) |

| Coolant inlet temperature (℃) | 15 |

| Coolant inlet diameter (mm) | 12 |

| Power consumption on cooling (kW) | 0.6kw (Driving), 0.75 (Charging) |

| Control power supply (V) | 9/36 |

| Contact area between water-cooling pack and battery pack (mm²) | 0.37 |

| Positions requiring thermal insulation | Whole vehicle battery compartments Whole vehicle water-cooling pipes |

| Outline dimensions (mm) | 1060 × 639 × 250 |

| Weight (kg) | Battery pack (subject to model selection) + Water-cooling pack (5kg) + Other accessories (7kg) |

| Fluid flow / Flow resistance | |||

|---|---|---|---|

| Qty of battery pack per pipe | Fluid flow required per battery pack | Flow resistance produced per battery pack | Temperature difference |

| 1 | 5L/min | 4kp | |

| 2 | 6L/min | 9kp | |

| 3 | 8L/min | 14kp | 1.2℃ (271Ah) |

| 4 | 10L/min | 21kp | 0.5~0.7℃ (271Ah) |